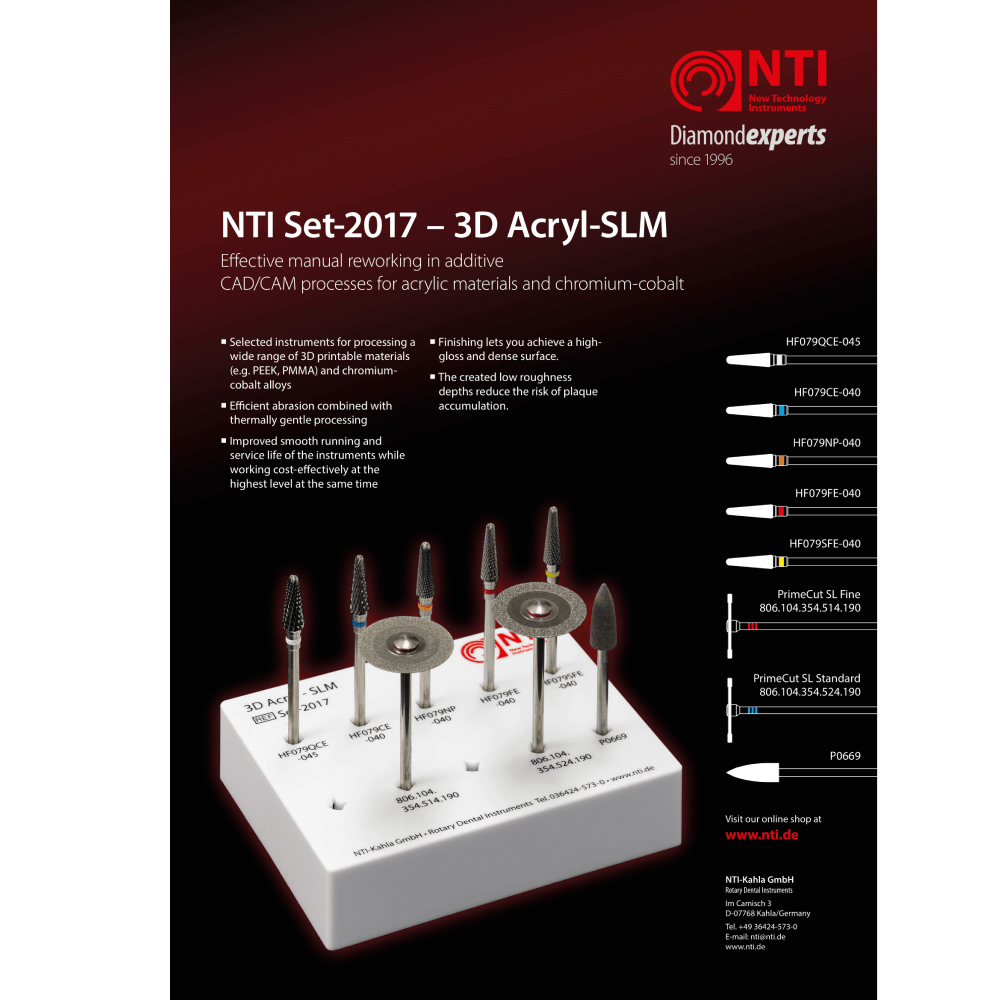

Specially selected instrument set for processing a wide range of 3D printable materials (e.g PEEK, PMMA) and chromium cobalt alloys, allowing effective manual re-working in additive CAD/CAM processes.

The efficient abrasion combined with thermally gentle processing, enables achievement of a high-gloss and dense surface finish whilst the created low roughness depths reduce the risk of plaque accumulation. This set provides improved smooth running and service life of the instruments while working cost effectively at the highest level.

Set comprises:

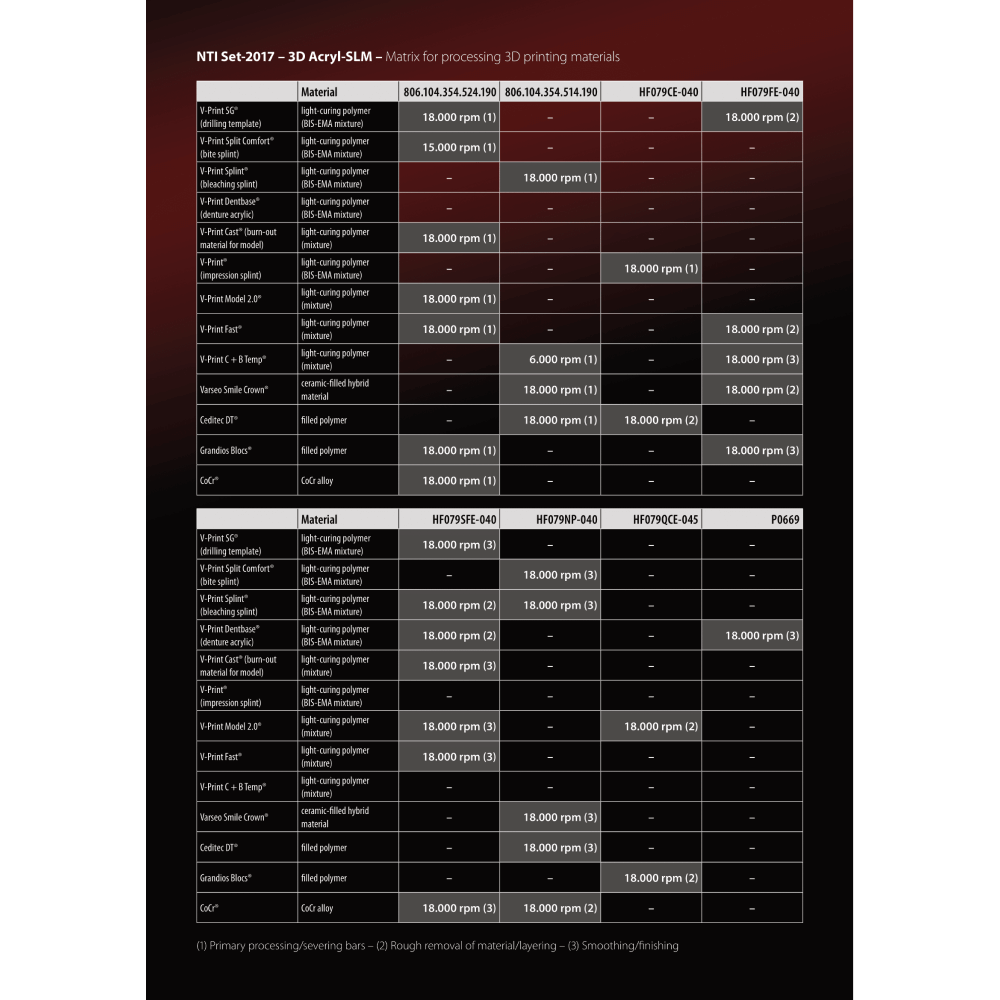

- HF079CE-040 Impression tray: Provides efficient abrasion without the risk of clogging the cutter, allowing working with less pressure, also reducing heat generation.

- HF079SFE-040 Denture Acrylic: The Cutting geometry is perfectly matched to the soft acrylic and enables a very smooth surface finish.

- HF079FE-040Drilling Template: The FE cut smooths the surface and enables the targeted finishing of specific structures.

- PrimeCut SL Fine Bleaching splint/bite splint: Due to its galvanic edge sintering, the fine grit offers an enormous cutting performance together with a long service life.

- HF079NP-040 CoCr alloy: Specifically suited for machining non ferrous metals and allows the creation of smooth surfaces at a particularly running smoothness.

- Prime Cut SL Standard Burn-out material: The diamond disc with medium grit offers the advantage of fast and clean processing of bars. In addition, galvanic edge sintering prevents contamination of the workpiece with foreign matter.

- HF079QCE Model 2.0: The QCE cross cut is particularly suitable for machining thermo-plastics. Efficient abrasion without requiring force reduces heat generation and is gentle on the material.

- P0699 Prosthesenkunststoff: The NTI Prothetics Polisher made of silicone is ideally suited for the fine pre-polishing of permanently soft acrylics.

- Product Code: SET2017